CAMWorks 2023 SP5 (08–12–2023) Win x64

"softddl.org"

30-12-2023, 21:01

-

Share on social networks:

-

Download for free: CAMWorks

-

Free Download CAMWorks 2023 SP5 | 1.6 Gb

Languages Supported: 中文 Simplified, 中文 Traditional, Français, Deutsch, Italiano

日本語, Polski, Português-Brazilian, Русский, Español, Türkçe, 한국어, Čeština

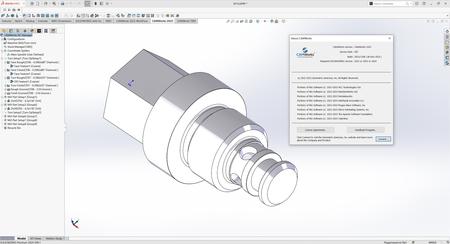

The HCLSoftware development team is pleased to announce the availability ofHCL CAMWorks 2023 SP5is an intuitive, feature-based CAM software that helps to increase productivity using best-in-class technologies and adaptable automation tools to maximize CNC machining efficiency.

Owner:HCL Technologies (HCL)

Product Name:CAMWorks

Version:2023 SP5 build 2023/1208 (08-Dec-2023)

Supported Architectures:x64

Website Home Page :www.camworks.com

Languages Supported:multilanguage

System Requirements:Windows *

Software Prerequisites:pre-installed SolidWorks 2022-2024

Size:1.6 Gb

,

Free Download CAMWorks 2023 SP5 | 1.6 Gb

Languages Supported: 中文 Simplified, 中文 Traditional, Français, Deutsch, Italiano

日本語, Polski, Português-Brazilian, Русский, Español, Türkçe, 한국어, Čeština

The HCLSoftware development team is pleased to announce the availability ofHCL CAMWorks 2023 SP5is an intuitive, feature-based CAM software that helps to increase productivity using best-in-class technologies and adaptable automation tools to maximize CNC machining efficiency.

Owner:HCL Technologies (HCL)

Product Name:CAMWorks

Version:2023 SP5 build 2023/1208 (08-Dec-2023)

Supported Architectures:x64

Website Home Page :www.camworks.com

Languages Supported:multilanguage

System Requirements:Windows *

Software Prerequisites:pre-installed SolidWorks 2022-2024

Size:1.6 Gb

,

1. CW-124214 CSR-24358 API

When executing the API macro "GetEnumRecords" for any Rough Mill or Contour Mill toolpath, an error message gets displayed and the macro stops working. However, it works correctly for Drilling toolpaths.

2. CW-124090 CSR-24304 Simulation

During Simulation mode, the Tool display for Dovetail tool is incorrect. However, if the 'Center cutting' checkbox under Tool tab of Operation Parameters dialog box is checked, then the tool gets displayed correctly.

3. CW-121896 CSR-23447 Feed Speed

For the Entry drill operation that are assigned tools with diameter in the range of 1mm to 7mm, the correct surface speed (SFM/SMM) is not retrieved from the Feed Speed Library.

4. CW-119885 CSR-22686 System

For the specific Mill part, CAMWorks gets repeatedly hanged when previewing operations containing WIP Rest Machining.

5. CW-119117 CSR-22313 Toolpath

For the specific Assembly, the 'Retract between features' option does not work correctly for the Single Point operation. This is observed when 'Retract between features' is set to 'Use skim plane' with a distance value assigned. The toolpath does not change when this distance value changes.

6. CW-110977 CSR-17803 Rebuild For the specific imported part, when user selected an *.igs file to replace the imported part, the CAMWorks Rebuild prompt pops-up. If the rebuild command is executed, then an error message stating "The CAMWorks features are no longer correct because there are two bodies in part." gets displayed and the CAMWorks rebuild fails.

CAMWorks for SOLIDWORKSwas the first fully integrated computer-aided manufacturing (CAM) solution designed exclusively to operate in SOLIDWORKS and the first to offer knowledge-based, feature recognition, and associative machining capabilities within SOLIDWORKS. CAMWorks uses the same SOLIDWORKS geometry to generate toolpaths to ensure the part you machine is the same part you've modeled. Toolpath simulation allows users to compare "as designed" parts to "as machined" parts. The part model-to-toolpath associativity in CAMWorks increases machining productivity and lowers manufacturing costs by eliminating time-consuming CAM system rework due to design updates. CAMWorks eliminates the drudgery of CNC programming with Intelligent Machining through automation. Pioneered by Geometric Technologies, this suite of tools automates the generation of toolpaths based on a knowledge-based database. It eliminates hours of complex programming through Automatic Feature Recognition (AFR) that automatically defines prismatic machinable features, while the TechDBTM (Technology Database) defines machining operations to automatically generate accurate toolpaths at the click of a button. CAMWorks machining modules include: 2½ Axis Mill, 3 Axis Mill, Turning, Mill-Turn with 5 Axis Simultaneous Machining Support, 4/5 Axis Simultaneous Machining, and Wire EDM.

CAMWorks 2023combines the benefits of a fully integrated CAD/CAM system with advanced programming technologies such as feature-based programming, automatic feature recognition, knowledge-based machining and TechDB for storing and reusing best practices.

What's new in CAMWorks 2023 - An overview

HCLSoftwareis a division of HCL Technologies (HCL) that operates its primary software business. We develop, market, sell, and support over 30 product families in the areas of Customer Experience, Digital Solutions, Secure DevOps, Security & Automation.

Buy Premium From My Links To Get Resumable Support,Max Speed & Support Me

Rapidgator-->Click Link PeepLink Below Here Contains Rapidgator

http://peeplink.in/5de33c02e6c9

NitroFlare

799ok.setup.rar

Uploadgig

799ok.setup.rar

Fikper

799ok.setup.rar.html

CAMWorks 2023 SP5 (08–12–2023) Win x64 Torrent Download , CAMWorks 2023 SP5 (08–12–2023) Win x64 Crack Download , CAMWorks 2023 SP5 (08–12–2023) Win x64 Patch Download , CAMWorks 2023 SP5 (08–12–2023) Win x64 Serial Keygen Download

The minimum comment length is 50 characters. comments are moderated