2 Minutes Funda Series Piping Engineering

"softddl.org"

8-05-2022, 21:45

-

Share on social networks:

-

Download for free: 2 Minutes

-

Published 05/2022

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz, 2 Ch

Genre: eLearning | Language: English + srt | Duration: 5 lectures (3h 46m) | Size: 1.95 GB

Published 05/2022

MP4 | Video: h264, 1280x720 | Audio: AAC, 44.1 KHz, 2 Ch

Genre: eLearning | Language: English + srt | Duration: 5 lectures (3h 46m) | Size: 1.95 GB

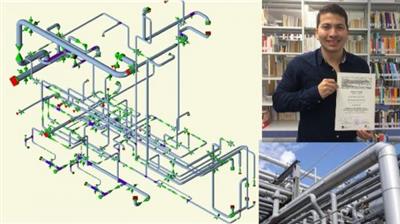

Fundamentals of Piping Engineering

What you'll learn

Piping Engineering Fundamentals

Funda w.r.t. Piping Components

Funda w.r.t. Piping Layouts

Funda w.r.t. Pipe Supporting

Requirements

Willingness to learn

Description

Piping System Fundamentals is a complete guide to gaining a clear picture of your piping system.

Understand codes and standards governing the design of pressure retaining components, pipe sizing, stress due to internal pressure.

A piping system is generally considered to include the complete interconnection of pipes, including in-line components such as pipe fittings and flanges. Pumps, heat exchanges, valves and tanks are also considered part of piping system.

Piping standards define application design and construction rules and requirements for piping components as flanges, elbows, tees, valves etc. - how to do it. A standard has a limited scope defined by the standard.

Proper piping material selection and system design controls the flow rate and velocity in a way that minimizes energy costs.

A piping system is crucial to any process plant; hence it needs to be designed with precision and care. The efficiency of a plant highly depends on its ability to transport fluid through the pipes to various equipment that function collectively.

ASME has been defining piping safety since 1922. ASME B31. 3 contains requirements for piping typically found in petroleum refineries; chemical, pharmaceutical, textile, paper, semiconductor, and cryogenic plants; and related processing plants and terminals.

In a fluid passing through a pipe, a reduction in the diameter of the pipe can compress the flowing fluid. It flows faster, which increases the flow rate. And if the diameter increases, then the flow rate reduces.

Carbon steel piping is a durable material made from carbon steel, a steel alloy with iron and carbon. Because of its strength and ability to withstand stress, carbon steel pipe is used in a variety of heavy-duty industries like infrastructure, ships, distillers, and chemical fertilizer equipment.

Code is a model that is adaptable by law. Standard is a set of technical definitions, specifications, and guidelines.

Basically ASTM creates the material specifications and standard test methods to determine compliance. ASME selects those ASTM materials which will perform adequately in boiler or pressure vessel service and accepts them with stated limitations.

Who this course is for

All Levels

Homepage

https://www.udemy.com/course/2-minutes-funda-series-piping-engineering/Links are Interchangeable - No Password - Single Extraction

The minimum comment length is 50 characters. comments are moderated